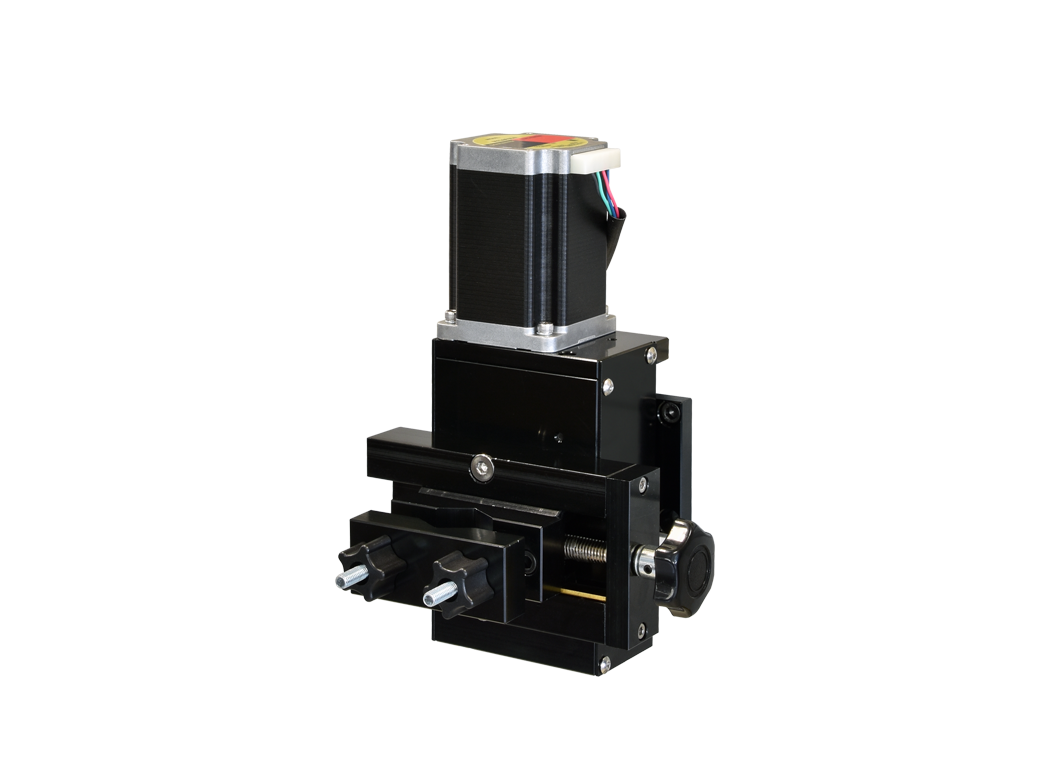

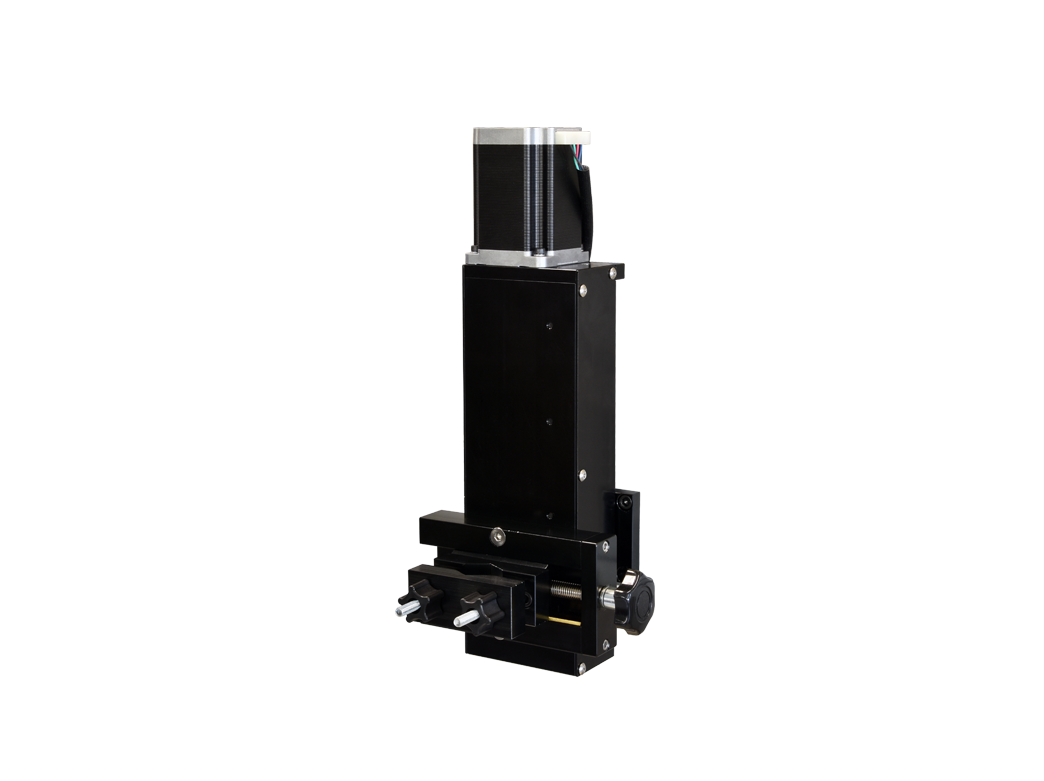

Arc Voltage Control System

ProArc AVC-150/AVC-25 systems utilize a control and drive unit to maintain precise TIG & plasma arc length in automated systems. Any variation in the arc gap is rapidly compensated for by continuous measurement of the arc voltage and a positional correction to the torch slide therefore maintaining a precise arc voltage.The system is easy to operate and integrates with a wide range of power supplies, torches, and positioners for assembling turn-key automation systems.